The High Speed V-Bottom Paper Bag Machine offers excellent speed and efficiency. With a max bag production speed of 500 pcs/min (RKJD-250) or 600 pcs/min (RKJD-350), it boosts productivity. The machine operates at speeds of up to 70 m/min (RKJD-250) or 120 m/min (RKJD-350), meeting high-demand production needs.

The adjustable paper bag cutting length (110-450 mm for RKJD-250 and 155-715 mm for RKJD-350) allows for versatile production. The width of the paper bag is customizable from 70-250 mm (RKJD-250) or 70-350 mm (RKJD-350), ensuring compatibility with various bag sizes.

Designed for easy operation, this machine efficiently handles side insert widths of 20-120 mm. It is ideal for businesses looking to scale their bag production and improve output.

This V-Bottom Paper Bag Machine is suitable for different industries, offering quick setup and reliable performance for high-volume production. Whether producing packaging for retail, food, or other uses, this machine meets a wide range of needs.

Product Parameters

Model | RKJD-250 | RKJD-350 |

Max. Paper bag speed | 500pcs/min | 600pcs/min |

Max. Machine speed | 70m/min | 120m/min |

| Paper bag cutting length (C) | 110-450mm | 155-715mm |

Paper bag width (W) | 70-250mm | 70-350mm |

Side insert width(G) | 20-120mm | 20-120mm |

Features of High Speed RKJD-250/350 V Bottom Paper Bag Machine

High-Speed Production: Capable of producing 500-600 bags per minute, ensuring efficient production.

Adjustable Sizes: Cutting length (110-450mm), bag length (140-390mm), and flap width (12-17mm) are customizable.

Durable Construction: Weighs 3500kg, built for long-term use in industrial environments.

Easy Operation: Computerized control minimizes downtime and increases production efficiency.

Comprehensive After-Sales Service: Offers video support, on-site installation, training, maintenance, and overseas engineer assistance.

Advantages of High Speed RKJD-250/350 V Bottom Paper Bag Machine

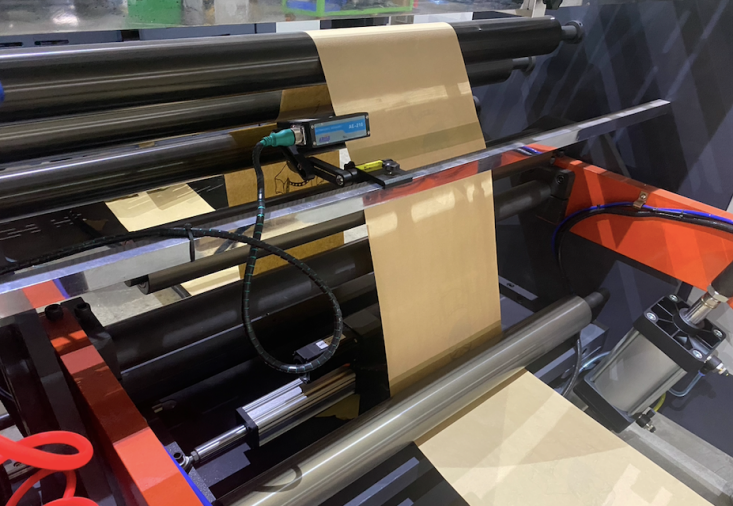

User Interface: Equipped with a touchscreen to display real-time working status.

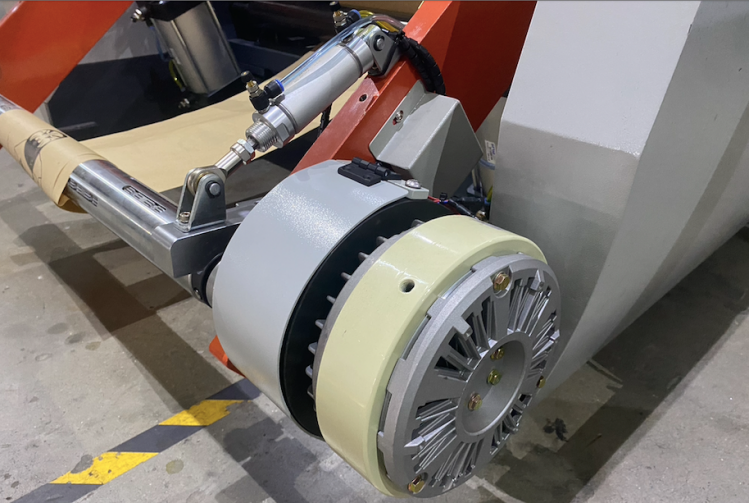

Servo Motor Drive: Ensures stable and efficient operation.

Pneumatic Lifting: Materials are lifted using a pneumatic structure for easy handling.

Tension Control System: Features a precision controller from Bellofram to maintain optimal tension.

Dual Photoelectric Sensors: Automatic misalignment correction for energy-saving and long service life.

Automatic Counting System: Users can set the desired count for automated production.

Color Tracking System: Automatically halts the machine if color deviation occurs.

Automatic Lubrication System: Reduces maintenance costs and ensures smooth operation.

Applications of High Speed RKJD-250/350 V Bottom Paper Bag Machine

Food Packaging: Ideal for producing food paper bags like bread bags, KFC bags, McDonald's bags, and more.

Large-Scale Production: Suitable for businesses requiring high-volume food packaging solutions.

FAQsof High Speed RKJD-250/350 V Bottom Paper Bag Machine

1.What is the maximum speed of the V-Bottom Paper Bag Machine?

The machine can produce up to 600 bags per minute at maximum speed.

2.What are the adjustable settings for this Paper Bag Machine?

The cutting length, bag length, and flap width are all adjustable for flexible production.

3.Can I customize the Paper Bag Machine for different bag sizes?

Yes, this machine is highly customizable and supports various bag dimensions, including width and length.

4.Is technical support available for the Paper Bag Machine?

Yes, we provide video technical support, on-site installation, training, and maintenance services.

5.What materials can the V-Bottom Paper Bag Machine handle?

The machine can work with different types of paper, including kraft and art paper.